All Exams >

Mechanical Engineering >

Design of Machine Elements >

All Questions

All questions of Cotter & Knuckle Joint for Mechanical Engineering Exam

The principle of wedge action is used in cotter joint.- a)True

- b)False

Correct answer is option 'A'. Can you explain this answer?

The principle of wedge action is used in cotter joint.

a)

True

b)

False

|

|

Nitin Joshi answered |

Explanation: Wedge action imparts tightening to the cotter joint.

Cotter joint is used when the members are subjected to which type of stresses?- a)Axial tensile

- b)Axial compressive

- c)Axial tensile or compressive

- d)None of the mentioned

Correct answer is option 'C'. Can you explain this answer?

Cotter joint is used when the members are subjected to which type of stresses?

a)

Axial tensile

b)

Axial compressive

c)

Axial tensile or compressive

d)

None of the mentioned

|

|

Nayanika Yadav answered |

Explanation: Cotter joint is used when axial forces are applied.

If any cross section is subjected to direct tensile stress and bending stress, then find the dimension of cross section. Given length & breadth are t and 2t respectively. F=25kN acts on the top fibre of the cross section, M=F x t . Also maximum allowable tensile stress =100N/mm².- a)25.5mm

- b)30.2mm

- c)27.55mm

- d)None of the mentioned

Correct answer is option 'A'. Can you explain this answer?

If any cross section is subjected to direct tensile stress and bending stress, then find the dimension of cross section. Given length & breadth are t and 2t respectively. F=25kN acts on the top fibre of the cross section, M=F x t . Also maximum allowable tensile stress =100N/mm².

a)

25.5mm

b)

30.2mm

c)

27.55mm

d)

None of the mentioned

|

|

Arnav Menon answered |

Explanation: σ= [P/A] + [My/I], where y=t & I=t(2t)ᴲ/12.

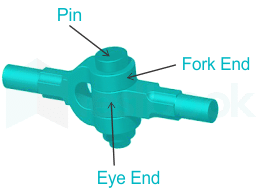

Which of the following are important parts of knuckle joint?- a)Eye

- b)Pin

- c)Fork

- d)Each of the mentioned

Correct answer is option 'D'. Can you explain this answer?

Which of the following are important parts of knuckle joint?

a)

Eye

b)

Pin

c)

Fork

d)

Each of the mentioned

|

|

Sharmila Chauhan answered |

Knuckle joint OR Forked Pin Joint:

- Knuckle joint is used to connect two rods whose axes either coincide or interact and lie in one plane.

- The knuckle joint is used to transmit axial tensile force.

- Permits limited angular movement between rods, about the axis of the pin.

- Unsuitabletoconnect two rotating shafts, which transmit torque.

- Applications:Valve mechanism of a reciprocating engine, bicycle chain, the fulcrum of a lever, etc.

- In rare applications, a knuckle joint is used to connect three rods, two with forks and one with the eye.

Hence Option (D) is correct.

For short notes on Knuckle Joint click on the following link:

A knuckle joint is unsuitable for two rotating shafts, which transmit torque- a)True

- b)False

Correct answer is option 'A'. Can you explain this answer?

A knuckle joint is unsuitable for two rotating shafts, which transmit torque

a)

True

b)

False

|

Aniket Pillai answered |

Knuckle Joint for Transmitting Torque

Explanation:

Therefore, it is true that a knuckle joint is unsuitable for two rotating shafts that transmit torque.

- True: A knuckle joint is unsuitable for two rotating shafts that transmit torque.

Explanation:

- Design Purpose: Knuckle joints are typically used in applications where there is a bending or oscillating motion rather than pure rotational motion.

- Limitation in Torque Transmission: Knuckle joints are not designed to withstand the twisting forces involved in transmitting torque between two rotating shafts.

- Mechanical Constraints: The design of a knuckle joint includes pins and links that are not optimized for torque transmission, leading to potential failures under high torque conditions.

- Alternative Solutions: For transmitting torque between rotating shafts, other types of couplings such as universal joints, gear couplings, or rigid couplings are more suitable as they are designed specifically for torque transmission.

Therefore, it is true that a knuckle joint is unsuitable for two rotating shafts that transmit torque.

Determine the width of the cotter used in cotter joint connecting two rods subjected to axial load of 50kN and permissible shear stress in cotter is 50N/(mm² ). Given thickness of cotter=10mm- a)5omm

- b)100mm

- c)150mm

- d)25mm

Correct answer is option 'A'. Can you explain this answer?

Determine the width of the cotter used in cotter joint connecting two rods subjected to axial load of 50kN and permissible shear stress in cotter is 50N/(mm² ). Given thickness of cotter=10mm

a)

5omm

b)

100mm

c)

150mm

d)

25mm

|

|

Ruchi Ahuja answered |

Explanation: Cotter is subjected to double shear hence width=P/(2*τ*t).

A maximum of how many roads may be connected using a knuckle joint?- a)2

- b)3

- c)4

- d)5

Correct answer is option 'B'. Can you explain this answer?

A maximum of how many roads may be connected using a knuckle joint?

a)

2

b)

3

c)

4

d)

5

|

|

Sagarika Dey answered |

Explanation: In rare explanation, two rods with forks and one rod with eye is connected.

Which of the following is not a part of cotter joint?- a)Socket

- b)Spigot

- c)Cotter

- d)Collar

Correct answer is option 'D'. Can you explain this answer?

Which of the following is not a part of cotter joint?

a)

Socket

b)

Spigot

c)

Cotter

d)

Collar

|

|

Gaurav Kapoor answered |

Explanation: There is no point of mentioning collar alone in a cotter joint. It has to be a spigot collar or socket collar.

If knuckle joint is to fail by crushing failure of pin in fork, then determine the diameter of knuckle pin when 50kN axial tensile force act on rods. Given: Max allowable compressive stress=25N/mm², thickness of each eye of fork=25mm.- a)40mm

- b)50mm

- c)60mm

- d)70mm

Correct answer is option 'A'. Can you explain this answer?

If knuckle joint is to fail by crushing failure of pin in fork, then determine the diameter of knuckle pin when 50kN axial tensile force act on rods. Given: Max allowable compressive stress=25N/mm², thickness of each eye of fork=25mm.

a)

40mm

b)

50mm

c)

60mm

d)

70mm

|

|

Avantika Sen answered |

Explanation: d=P/2aσ = 40mm.

A knuckle joint is also called socket pin joint.- a)True

- b)False

Correct answer is option 'B'. Can you explain this answer?

A knuckle joint is also called socket pin joint.

a)

True

b)

False

|

Sanaya Sengupta answered |

Knuckle Joint and Socket Pin Joint:

A knuckle joint and a socket pin joint are two different types of joints used in mechanical engineering. Although they have some similarities, they are not the same.

Knuckle Joint:

A knuckle joint is a type of mechanical joint that is used to connect two rods or bars. It consists of a pin or bolt that passes through a pair of loops or eyes formed at the ends of the rods. The pin or bolt is usually cylindrical in shape and allows the rods to rotate freely around it. This joint is commonly used in situations where flexibility and rotational movement are required.

Socket Pin Joint:

A socket pin joint, on the other hand, is a type of joint that consists of a socket or housing and a pin or bolt. The socket is typically a hollow cylinder with a hole through it, while the pin or bolt is a cylindrical object that fits snugly into the hole. The pin or bolt is inserted into the socket, allowing the two parts to rotate or move relative to each other. This type of joint is commonly used in applications where a rigid connection is required.

Explanation of the Answer:

The given statement "A knuckle joint is also called a socket pin joint" is false. The two terms refer to different types of joints. A knuckle joint is a type of joint that allows rotational movement, while a socket pin joint provides a rigid connection between two parts.

Conclusion:

In conclusion, a knuckle joint and a socket pin joint are not the same. A knuckle joint allows rotational movement, while a socket pin joint provides a rigid connection. It is important to understand the differences between these two types of joints to ensure their correct application in mechanical engineering.

A knuckle joint and a socket pin joint are two different types of joints used in mechanical engineering. Although they have some similarities, they are not the same.

Knuckle Joint:

A knuckle joint is a type of mechanical joint that is used to connect two rods or bars. It consists of a pin or bolt that passes through a pair of loops or eyes formed at the ends of the rods. The pin or bolt is usually cylindrical in shape and allows the rods to rotate freely around it. This joint is commonly used in situations where flexibility and rotational movement are required.

Socket Pin Joint:

A socket pin joint, on the other hand, is a type of joint that consists of a socket or housing and a pin or bolt. The socket is typically a hollow cylinder with a hole through it, while the pin or bolt is a cylindrical object that fits snugly into the hole. The pin or bolt is inserted into the socket, allowing the two parts to rotate or move relative to each other. This type of joint is commonly used in applications where a rigid connection is required.

Explanation of the Answer:

The given statement "A knuckle joint is also called a socket pin joint" is false. The two terms refer to different types of joints. A knuckle joint is a type of joint that allows rotational movement, while a socket pin joint provides a rigid connection between two parts.

Conclusion:

In conclusion, a knuckle joint and a socket pin joint are not the same. A knuckle joint allows rotational movement, while a socket pin joint provides a rigid connection. It is important to understand the differences between these two types of joints to ensure their correct application in mechanical engineering.

Thickness of plate is required more in welding than in riveting.- a)True

- b)False

Correct answer is option 'B'. Can you explain this answer?

Thickness of plate is required more in welding than in riveting.

a)

True

b)

False

|

|

Nitin Joshi answered |

Explanation:

Plate Thickness in Welding vs. Riveting:

- In welding, the thickness of the plate is required to be more compared to riveting.

- This is because welding involves the fusion of two metal pieces together, requiring a certain thickness of the plate to ensure a strong and durable bond.

- Thicker plates provide more material for the welding process, allowing for better penetration and stronger joints.

- Additionally, thicker plates can help distribute the heat more evenly during welding, reducing the risk of distortion or warping.

- On the other hand, riveting involves joining metal pieces using mechanical fasteners such as rivets.

- Riveting does not rely on the thickness of the plate for strength, as the rivets themselves provide the necessary support for the joint.

- Therefore, thinner plates can be used in riveting compared to welding, as the strength of the joint comes from the rivets rather than the plate itself.

In conclusion, the thickness of the plate is required more in welding than in riveting due to the different joining processes and mechanisms involved in each method.

Plate Thickness in Welding vs. Riveting:

- In welding, the thickness of the plate is required to be more compared to riveting.

- This is because welding involves the fusion of two metal pieces together, requiring a certain thickness of the plate to ensure a strong and durable bond.

- Thicker plates provide more material for the welding process, allowing for better penetration and stronger joints.

- Additionally, thicker plates can help distribute the heat more evenly during welding, reducing the risk of distortion or warping.

- On the other hand, riveting involves joining metal pieces using mechanical fasteners such as rivets.

- Riveting does not rely on the thickness of the plate for strength, as the rivets themselves provide the necessary support for the joint.

- Therefore, thinner plates can be used in riveting compared to welding, as the strength of the joint comes from the rivets rather than the plate itself.

In conclusion, the thickness of the plate is required more in welding than in riveting due to the different joining processes and mechanisms involved in each method.

Can the cotter joint be used to connect slide spindle and fork of valve mechanism?- a)True

- b)False

Correct answer is option 'A'. Can you explain this answer?

Can the cotter joint be used to connect slide spindle and fork of valve mechanism?

a)

True

b)

False

|

|

Gaurav Kapoor answered |

Explanation: As long as axial forces act, cotter joint can be employed.

A knuckle joint can be used in valve mechanism of a reciprocating engine.- a)Yes

- b)No

- c)Yes but there are stress probles

- d)No as it is very dangerous to use

Correct answer is option 'A'. Can you explain this answer?

A knuckle joint can be used in valve mechanism of a reciprocating engine.

a)

Yes

b)

No

c)

Yes but there are stress probles

d)

No as it is very dangerous to use

|

|

Samarth Chaudhary answered |

Explanation: Knuckle joint can be used till the rods coincide or intersect in a plane.

Calculate the diameter of pin from shear consideration with maximum shear stress allowed is 40NN/mm² and an axial tensile force of 50kN is acting on the rod.- a)39mm

- b)44mm

- c)49mm

- d)52mm

Correct answer is option 'A'. Can you explain this answer?

Calculate the diameter of pin from shear consideration with maximum shear stress allowed is 40NN/mm² and an axial tensile force of 50kN is acting on the rod.

a)

39mm

b)

44mm

c)

49mm

d)

52mm

|

|

Yash Das answered |

Explanation: As the pin is subjected to double shear diameter (D) = √(2P/π x τ) = 38.80mm.

Knuckle Joint can’t be used to connect two intersecting rods.- a)Yes

- b)No, it can’t be used

- c)It can be used with some modificatios

- d)It is expensive and hence isn’t used

Correct answer is option 'B'. Can you explain this answer?

Knuckle Joint can’t be used to connect two intersecting rods.

a)

Yes

b)

No, it can’t be used

c)

It can be used with some modificatios

d)

It is expensive and hence isn’t used

|

|

Debolina Menon answered |

Be used in various applications including:

1. Automotive industry: Knuckle joints are commonly used in car suspension systems to connect the steering knuckle to the control arms. They allow for rotational movement and help in steering the vehicle.

2. Industrial machinery: Knuckle joints are used in heavy-duty machinery and equipment to provide flexibility and allow for angular movement. They are commonly found in cranes, excavators, and mining equipment.

3. Construction: Knuckle joints are used in construction equipment such as forklifts and loaders to provide articulation and flexibility in movement.

4. Aerospace: Knuckle joints are used in aircraft control systems to transmit motion from the control surfaces to the control rods. They allow for precise control and adjustment of the aircraft's flight controls.

5. Robotics: Knuckle joints are used in robotic arms and manipulators to provide articulation and flexibility in movement. They allow for precise control and positioning of robot end-effectors.

Overall, knuckle joints are versatile components that are used in various industries and applications where rotational and angular movement is required.

1. Automotive industry: Knuckle joints are commonly used in car suspension systems to connect the steering knuckle to the control arms. They allow for rotational movement and help in steering the vehicle.

2. Industrial machinery: Knuckle joints are used in heavy-duty machinery and equipment to provide flexibility and allow for angular movement. They are commonly found in cranes, excavators, and mining equipment.

3. Construction: Knuckle joints are used in construction equipment such as forklifts and loaders to provide articulation and flexibility in movement.

4. Aerospace: Knuckle joints are used in aircraft control systems to transmit motion from the control surfaces to the control rods. They allow for precise control and adjustment of the aircraft's flight controls.

5. Robotics: Knuckle joints are used in robotic arms and manipulators to provide articulation and flexibility in movement. They allow for precise control and positioning of robot end-effectors.

Overall, knuckle joints are versatile components that are used in various industries and applications where rotational and angular movement is required.

In cold riveting like hot riveting shank is subjected to majorly tensile stress.- a)True

- b)False

Correct answer is option 'B'. Can you explain this answer?

In cold riveting like hot riveting shank is subjected to majorly tensile stress.

a)

True

b)

False

|

|

Ayush Chawla answered |

Explanation: In cold riveting there is no reduction in length and hence no tensile stress. Shear stress dominates.

Cold riveting holds the connected parts better than hot riveting.- a)True

- b)False

Correct answer is option 'B'. Can you explain this answer?

Cold riveting holds the connected parts better than hot riveting.

a)

True

b)

False

|

|

Dipika Bose answered |

Explanation: The compression of connected parts in hot riveting causes friction, which resist sliding of one part with respect to other. This force is greater in hot riveting.

Cotter joint can be used to connect two rods for torque transmission purpose.- a)True

- b)False

Correct answer is option 'B'. Can you explain this answer?

Cotter joint can be used to connect two rods for torque transmission purpose.

a)

True

b)

False

|

|

Nayanika Yadav answered |

Explanation: Cotter Joint is never used to connect two rods for torque transmission purpose.

Chapter doubts & questions for Cotter & Knuckle Joint - Design of Machine Elements 2025 is part of Mechanical Engineering exam preparation. The chapters have been prepared according to the Mechanical Engineering exam syllabus. The Chapter doubts & questions, notes, tests & MCQs are made for Mechanical Engineering 2025 Exam. Find important definitions, questions, notes, meanings, examples, exercises, MCQs and online tests here.

Chapter doubts & questions of Cotter & Knuckle Joint - Design of Machine Elements in English & Hindi are available as part of Mechanical Engineering exam.

Download more important topics, notes, lectures and mock test series for Mechanical Engineering Exam by signing up for free.

Design of Machine Elements

49 videos|102 docs|77 tests

|

Contact Support

Our team is online on weekdays between 10 AM - 7 PM

Typical reply within 3 hours

|

Free Exam Preparation

at your Fingertips!

Access Free Study Material - Test Series, Structured Courses, Free Videos & Study Notes and Prepare for Your Exam With Ease

Join the 10M+ students on EduRev

Join the 10M+ students on EduRev

|

|

Create your account for free

OR

Forgot Password

OR

Signup to see your scores

go up within 7 days!

Access 1000+ FREE Docs, Videos and Tests

Takes less than 10 seconds to signup